The Power of Honeycomb Panels in the Automotive Industry

In the automotive industry, innovative materials and technologies are continually helping to make production processes more efficient, safe, and environmentally friendly. In recent years, honeycomb panel material has brought about a significant revolution, particularly in the transport of automotive spare parts. Thanks to its lightweight, durable, and flexible structure, this material plays a key role in enhancing the transportation and storage processes. The honeycomb panel is much more than just a packaging solution: it ensures the safe delivery of parts, reduces costs, and boosts efficiency.

What is a Honeycomb Panel and Why is it Preferred in the Automotive Industry?

A honeycomb panel is a lightweight, highly durable material with a hexagonal cell structure. This unique cellular design provides excellent resistance to impact while maintaining an ideal balance between lightness and strength. Made from recycled paper, these panels can be easily customized in different sizes and shapes. The biggest advantage of honeycomb panels in the automotive industry is their superior impact absorption, which prevents damage to products during transportation. In addition, the efficiency it brings to production and storage processes makes this material an indispensable choice in the sector.

The Role of Honeycomb Panels in the Safe Transport of Spare Parts

Automotive spare parts go through many challenging stages, from design and manufacturing to transportation. Transporting fragile parts requires high-security measures. Parts like vehicle windows, engine components, hoods, and trunk lids are particularly susceptible to damage during transportation. This is where honeycomb panel material comes into play. The hexagonal cell structure absorbs impacts during transit, ensuring that parts arrive at their destination safely.

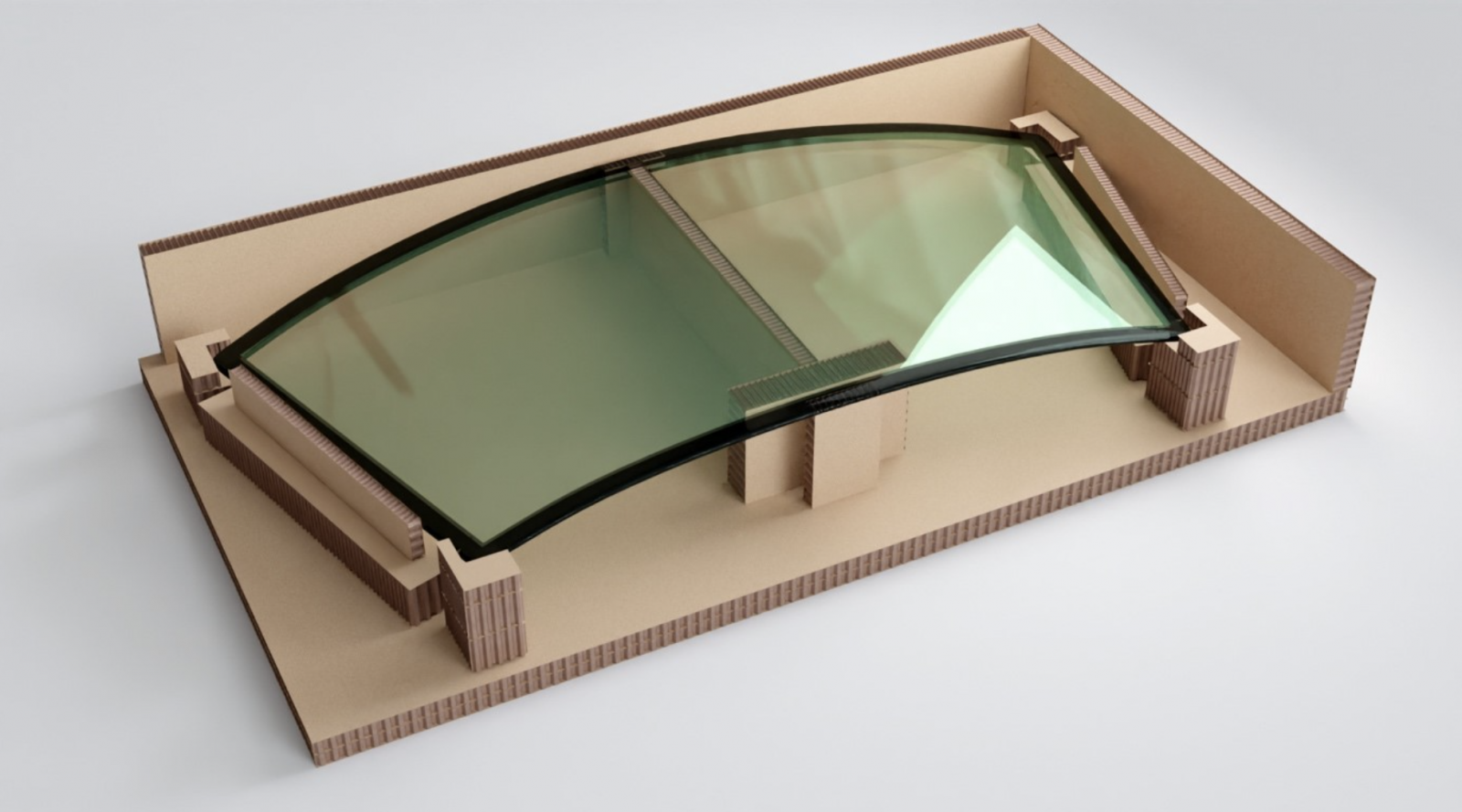

For example, vehicle windows are among the most delicate parts to transport. Due to their fragile nature, windows are at high risk during shipping. Honeycomb panel packaging acts like a protective shield around the glass, providing highly effective protection against impacts. Each cell absorbs the shock, preserving the integrity of the glass and enhancing the security of the transport process. This ensures that not only windows but all fragile automotive parts can be transported without damage.

Customizable Packaging for Spare Parts Based on Shape

Another significant advantage of honeycomb panels is the ability to create customized packaging solutions for various parts during transportation. Spare parts are typically of different sizes and shapes, each requiring special handling. Honeycomb panels, with their flexible structure, are ideal for producing boxes and transport crates that can be tailored for each part. This allows every automotive component to be safely and securely delivered to its destination without damage.

This customization offers significant benefits to manufacturers and logistics companies. Honeycomb panel packaging can be designed in different sizes and shapes for each part, ensuring the most suitable transport conditions. This prevents unnecessary movement during transport, keeping parts secure. Additionally, multiple parts can be transported within the same packaging without touching each other, resulting in substantial space and cost savings.

Use of Honeycomb Panels in Trunk Design

The use of honeycomb panels in the automotive sector is not limited to transportation. Another important application is in the design of trunk panels and trunk lids. The use of honeycomb panels in the interior structure of the trunk reduces the weight of the vehicle while enhancing the durability and security of the trunk. Large and heavy parts, such as trunk lids, can be transported with less weight thanks to honeycomb panels, which also contributes to better fuel efficiency of the vehicle.

Additionally, the aerodynamic properties of honeycomb panels can positively affect the performance of the vehicle. This material in the trunk not only serves a transportation and storage function but also helps optimize the vehicle's exterior design. This brings important contributions in terms of both safety and performance.

Impact of Honeycomb Panels on Efficiency

Honeycomb panel materials also stand out for their efficiency in transport and storage processes. The lightness of the material reduces the need for labor during handling, enabling workers to be more efficient. Moreover, the stackability of honeycomb panels allows transport containers to be used more efficiently, helping reduce transportation costs. The more efficient use of space in transport also creates significant advantages in storage.

Many automotive manufacturers and supply chain companies are taking advantage of these features, using the benefits of honeycomb panels to enhance sustainability, efficiency, and safety in production and logistics processes. This material has become a key tool in the industry, offering much more than just a packaging solution.

The Future of Honeycomb Panels in the Automotive Sector

Honeycomb panel materials have become indispensable tools for both manufacturers and logistics companies in the automotive industry. The safety, ease of transport, cost-effectiveness, and efficiency they provide make them one of the most valuable materials in the sector. Honeycomb panels will continue to play a key role as one of the automotive industry's most important solution partners, shaping the future of the sector.

For more information about our solutions for the automotive sector, feel free to contact us!