Towards Change: The Coming EPS Ban and the Promotion of Honeycomb Panel Packaging in the White Goods Industry

At a time when sustainability and environmental responsibility are increasingly emphasized, the environmental damage caused by polystyrene (EPS) is leading countries to take legislative steps to switch to alternative packaging. This is forcing manufacturers across the continent to re-evaluate their packaging practices.

A staple material for packaging due to its lightweight and insulating properties, Expanded Polystyrene has long been under investigation for its environmental impacts, including its non-biodegradability and recycling challenges. The material, which requires significant amounts of energy and resources to produce, creates long-term environmental pollution.

The planned Europe-wide polystyrene ban underlines a collective commitment to reduce plastic waste and promote greener business practices. While various European countries are moving towards restricting or phasing out polystyrene, France is the first country to take full responsibility for the targeted regulations, banning the use of Expanded Polystyrene (EPS) completely in 2025. With this ban, many sectors, especially the white goods industry, are being brought to the brink of a significant transformation. Manufacturers are looking for ways to redesign their packaging strategies to adapt to these evolving standards.

The shift away from EPS requires a restructuring of packaging materials, supply chains and processes. Restructuring can potentially lead to increased costs and operational challenges. However, this shift also presents a unique opportunity for innovation and differentiation in a competitive market environment.

A sustainable packaging alternative: Honeycomb Panel

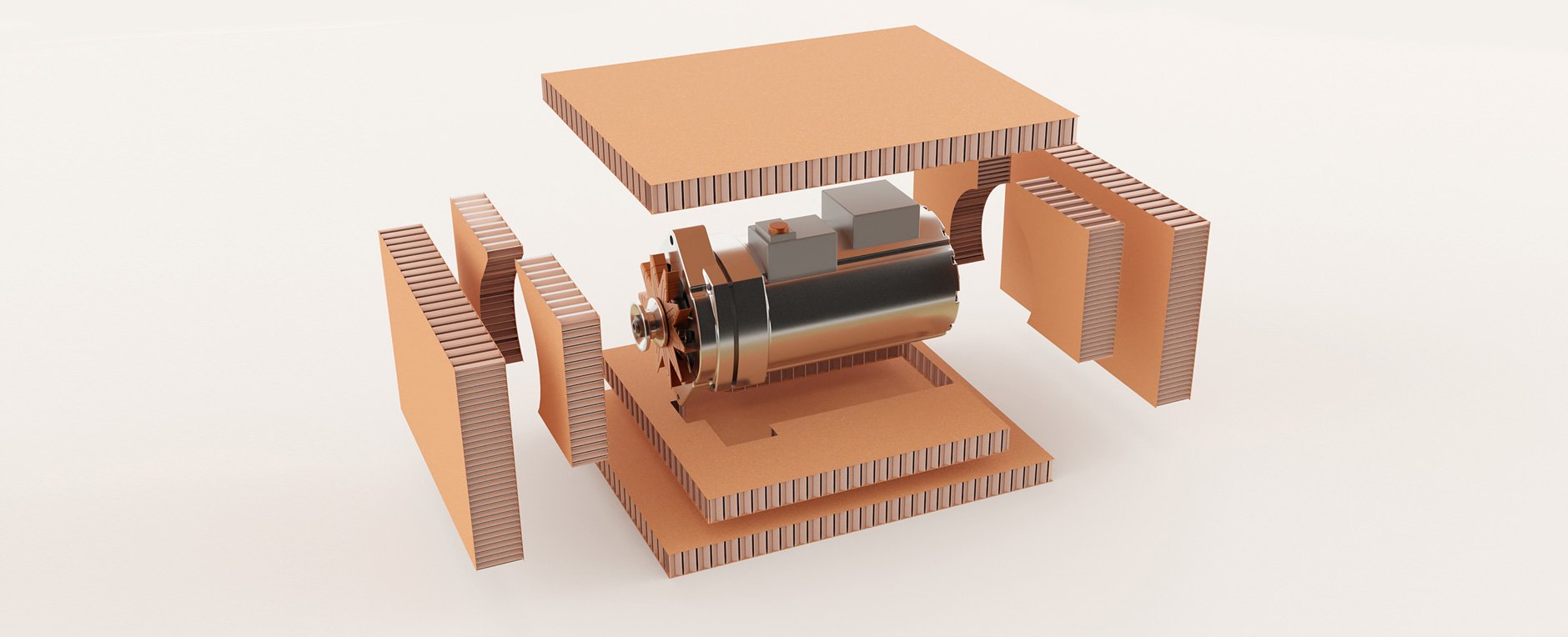

In the new search environment brought about by the EPS ban, honeycomb panel is emerging as a versatile alternative for packaging products in white goods and other industries. Made entirely from recycled paper, honeycomb panel packaging offers a biodegradable option that complies with circular economy principles, reduces the industry's environmental footprint and supports sustainable practices.

Let's take a closer look at how honeycomb panel packaging is replacing polystyrene:

1. Enhanced Protection: Honeycomb construction offers superior shock absorption and cushioning, ensuring safe transportation, protecting products from impact damage and minimizing risks to structural integrity during delivery.

2. Customizability: It can be customized to fit the exact dimensions of the products with its easy-to-shape structure, taking the shape of the product it holds.

3. Sustainability: Biodegradable, 100% recyclable and can be re-introduced into the supply chain.

4. Aesthetics: Eliminates visual concerns with product-specific designs.

Adoption of honeycomb panel material is emerging as the most strategic choice for companies that want to survive in a dynamic market environment. Manufacturers who want to adapt to evolving regulatory requirements and consumer expectations at the same time have been working on the transition to honeycomb panel packaging for some time.

France's EPS ban, which is scheduled to take effect in 2025, is actually part of a broader strategy to reduce plastic pollution, promote sustainable practices and move towards environmentally friendly alternatives. With the ongoing development of the United Nations Agreement on Plastic Pollution, change is expected to spread across the globe in the coming years. As a key player in this shift, honeycomb panel material is expected to be widely used as an EPS alternative in all industries in the near future.

If you want to be a part of this inevitable change, you can contact us and get information about our solutions.